HOT OIL HOSES

Our Hot Oil Hoses are annularly corrugated stainless steel hoses made of 1.4571 for water or thermo oil, 10 bar, 220 C, R-650 mm, Type RS331L121 with single or double ply stainless steel wire braiding, 1.4301, with friction lining and separate welded braiding with both end with shoulder sockets with loose rectangular Flanges. Other Flanges are available upon request. We supply hoses for Siempelkamp and other Presses in following diameters DN65, DN80 DN100 and DN32 for return hoses. Other diameters are available upon request. Hoses with external heat protecting insulation are also available.

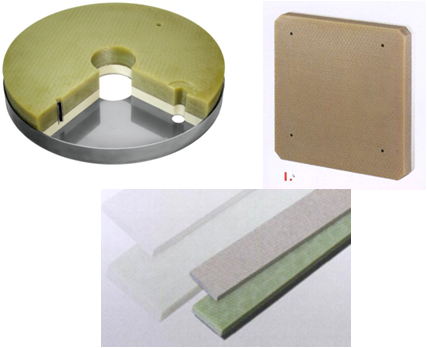

THERMAL PRESS INSULATION

The wood panel industries work with heated tooling when material is pressed directly between hot platens. If a platen is mounted to the press table without a layer of protective insulation, a considerable amount of heat is transferred to the press and the press heats up. In hydraulic presses, not only do the tables, beams and frames heat up, but so do the pistons and hydraulic fluid. This causes premature wear to packings in the entire system. Insulation is a very effective method to precisely control and manage heat in the cycle process to improve the performance and longevity of the press.

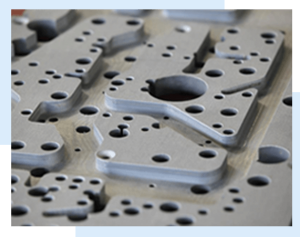

COMPENSATION INLAY

The compensation inlay AE 2000 N is used to compensate for uneven surfaces and plane parallelism defects in heated presses caused by wear and tear and corrosion. It is mounted at the rear side of the heating platens, above or beneath the insulation layer, depending on the thickness of the insulation and the temperature of the heating platens.

It cures in the press after installation. The use of this compensation inlay can delay a complete overhaul or replacement of press platens by many years.

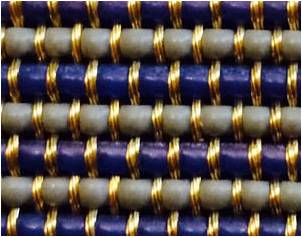

PRESS PADS

Press pads are used for the uniform transfer of pressure and heat in hydraulic presses. For the laminating of wood-based panels with duro-plastic resin film, bonding with liquid resins/ glue films, manufacture of concrete shuttering boards or high pressure Iaminates, the quality of the finished products depends to a Iarge extent on a steady pressure onto the surface of the product. In addition, press pads ensure a constant movement of thermal energy from the heating plate to the press plate surface. Our press pad SINAS VITO S is used in low pressure cycle and plywood lamination. Press Pad K400 R is perfect for bonding with liquid resins.