Parts for woodworking industry

Hot Oil Hoses

Our Hot Oil Hoses are expertly crafted from annularly corrugated stainless steel, specifically utilizing grade A240M 316L, designed for the efficient transport of water or thermal oil. These hoses are rated for a maximum pressure of 10 bar and can withstand temperatures up to 232°C. The model specifications include an R-650 mm length and Type RS331L121, featuring either single or double-ply stainless steel wire braiding made from A580M 304.

Each hose is equipped with a friction lining and separate braiding, ensuring durability and reliability. Both ends of the hoses are fitted with shoulder sockets and loose rectangular flanges, with alternative flange options available upon request.

We provide hoses compatible with Siempelkamp and other press systems in the following diameters: DN65, DN80, DN100, and DN32 for return hoses. Additional diameters can be supplied upon request. For enhanced protection, hoses with external heat insulation are also available.

Please contact us for further information or to discuss your specific requirement.

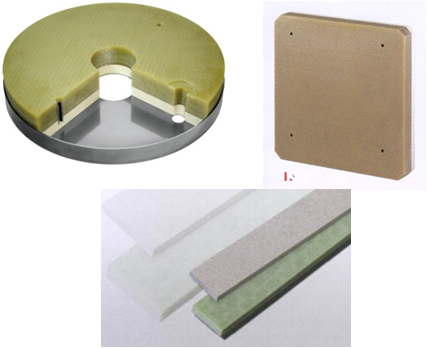

Thermal Press Insulation

The wood panel industry utilizes heated tooling, where materials are pressed directly between hot platens. When a platen is mounted to the press table without a layer of protective insulation, a significant amount of heat is transferred to the press itself, causing it to heat up. In hydraulic presses, this heat transfer affects not only the tables, beams, and frames but also the pistons and hydraulic fluid, leading to premature wear of the sealing components throughout the entire system.

Implementing insulation is an effective strategy for precisely controlling and managing heat during the cycle process, thereby enhancing both the performance and longevity of the press. Insulation also minimizes heat loss from the hot platens, resulting in more efficient heating of the work material and reduced energy consumption, as the press requires less energy to maintain the desired temperature.

Moreover, effective insulation improves the consistency and uniformity of heat applied to the work material, which is crucial for processes such as the hot pressing of wood- based composites, where precise temperature control significantly influences the properties of the final product. In certain instances, enhanced insulation can even improve the flow characteristics of the materials being molded or pressed.

Additionally, when used in conjunction with compensation pads placed between the hot platen and the insulation board, insulation can enhance the accuracy and parallelism of the press, even in older machines. This improvement can lead to tighter tolerances and a reduced need for shimming, ultimately contributing to higher quality outcomes in production.

Compensation Inlay

The AE 2020 compensation inlay is specifically designed to address issues of uneven surfaces and plane parallelism defects in heated presses, which may arise due to wear and tear or corrosion over time. This innovative solution is strategically mounted on the rear side of the heating platens, either above or below the insulation layer, depending on the insulation thickness and the operating temperature of the heating platens.

Once installed, the inlay cures within the press, effectively restoring functionality. By utilizing the AE 2020 compensation inlay, operators can significantly extend the lifespan of their press platens, potentially delaying the need for a complete overhaul or replacement by several years. This not only enhances operational efficiency but also contributes to cost savings in maintenance and equipment management.

Press Pads

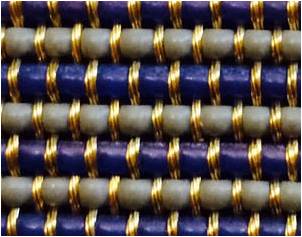

Press pads play a crucial role in ensuring the uniform transfer of pressure and heat in hydraulic presses. They are essential in various applications, including the lamination of wood-based panels with duro-plastic resin films, bonding with liquid resins or glue films, and the production of concrete shuttering boards and high-pressure laminates. The quality of the finished products is significantly influenced by the consistent application of pressure across the surface.

Moreover, press pads facilitate the efficient transfer of thermal energy from the heating plate to the surface of the press plate, enhancing the overall effectiveness of the pressing process. Our SINAS VITO S press pad is specifically designed for low- pressure cycles and plywood lamination, while the Press Pad K400 R is ideal for applications involving bonding with liquid resins. These products are engineered to meet the highest standards of performance, ensuring superior results in your manufacturing processes.